This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Unisnacks integrates Warehouse Management System in their Biggleswade Warehouse

Unisnacks integrates Warehouse Management System in their Biggleswade Warehouse

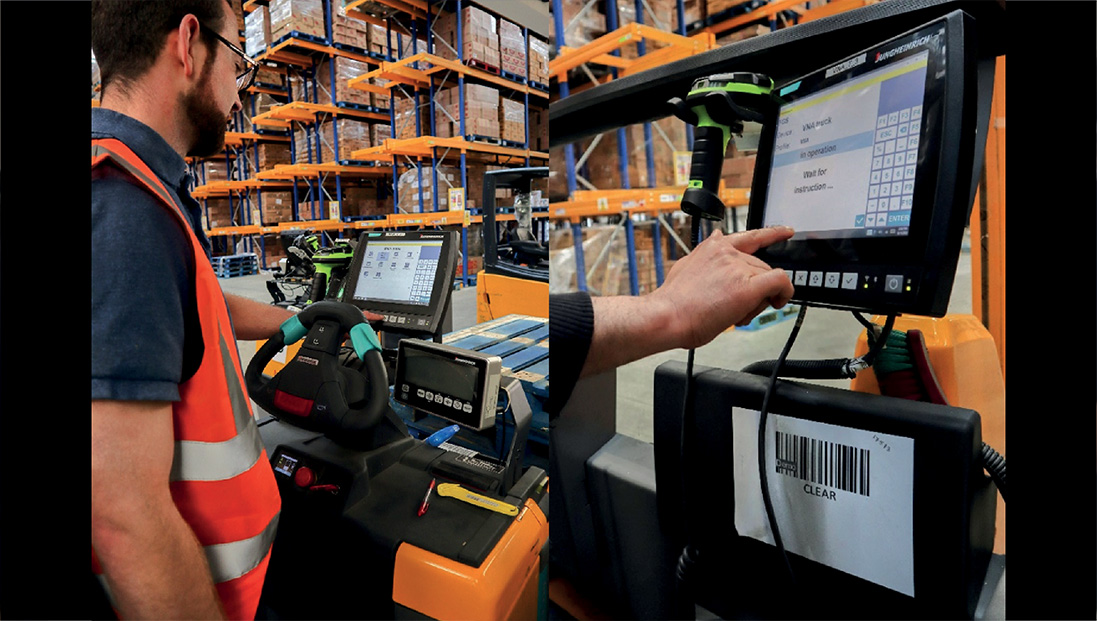

Unisnacks Europe Ltd has recently integrated Jung Heinrich WMS to manage, control and optimize their new warehouse in Biggleswade, UK.

What is WMS?

The warehouse management system (WMS) provides businesses with visibility into their entire inventory. It manages the supply chain from the warehouse to the store shelf.

A Warehouse Management (WMS) solution can also increase labour, space, and equipment utilization by coordinating and optimizing the use of resources and materials. More specifically, WMS systems support a whole supply chain, including distribution, manufacturing, asset-intensive businesses, and service providers.

Thanks to our AI-driven warehouse management system, we can eliminate human error and minimise our overheads. Our state-of-the-art warehouse management system manages our inbound and outbound logistics in real time, streamlining our day-to-day operations and ensuring all orders are fulfilled on time. This means the hub of our world foods wholesale operation runs as effectively and efficiently as possible. And we’re able to create an improved supply chain, offer our suppliers great deals and give our customers extremely competitively priced products.